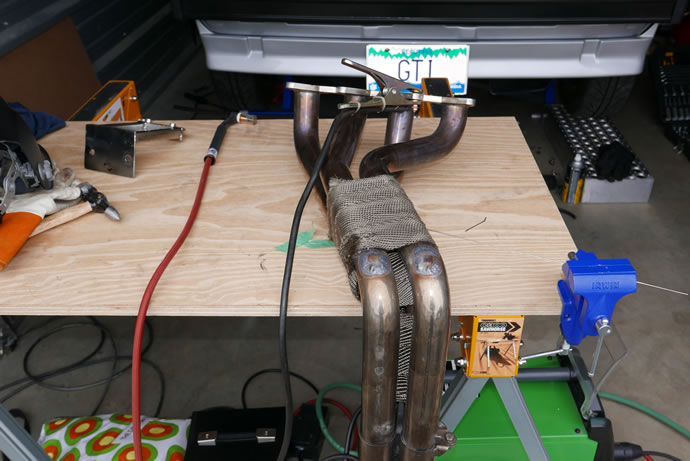

Project Ultimate 83 GTI

Performance Validation ...

The timeline story of the performance validation/testing work on the road and at the track

Back in 1983 the VW Rabbit GTI delivered 0-60mph times of 9.7s and 1/4 mile performance of 17.7s @ 77mph. Those numbers seems very slow by today's standards, but they were class leading #s in the day (see all of the magazine reviews posted on my original GTI page).

33 years to the month, my GTI sat again in my childhood home’s driveway: I took delivery of my original GTI in May of ’83 but it didn’t get licensed until August ’83 (no job, no money, no license …).

I drove about 3 hours in the car in total today - yes it was driven in the rain and got nice and dirty (I took my family and my dad out for rides), shaking out the initial bugs and gremlins. It will be about 1-2 months to get the car behaving the part (fast, fun, safe and semi-civilized). I discovered lots of things that need addressing already: the brakes are a bit mushy and need professional bleeding, the steering alignment also could use a pro setup alignment, there are some squeaks and rattles, the fuel gauge needs calibration, one of the radiator fans is DOA (I don’t think I will need 2 after all so maybe it will just be disabled), for some reason the engine shuts off at 6,000rpm, just as the fun starts, there was a fuel leak when I topped up the tank, the windows don’t roll up properly, it is a bit harsh and noisy, etc - you get the idea ...

The GTI is spending the night at the mechanics and should be certified road worthy tomorrow so it can be fully licensed. I will then have time to run system diagnostics on the crank and cam triggers - I suspect that the old-school analog inductive crank sensor is crapping out and may have to be replaced with an external digital hall effect crank sensor (which requires that a 60-2 tooth wheel be placed between the crank pulley and the crank itself). There may be something else going on but the computer says 'lost sync' in the RPM readout and the ECU goes a bit nuts for a while so ...

With fuel in the tank, carpet mats, A/C, stereo, sun-roof, full interior, etc. it scaled in at 1950lbs, with a 66/33 weight distribution. With some of this crap pulled out on race days I'll have an 1800lbs car.

I have 3/4" gaps from the top of the tires to the fenders all-round so ride height is perfect. Suspension is H&R race springs and Bilstein race struts and shocks. A bit stiff but not as bad as I thought it might be. Still, I will also order in some H&R sport springs and try them out - September 1, 2016

I got the car inspected, certified road worthy, and licensed this week and then went out and drove it around for more than 3 hours - what a joy!

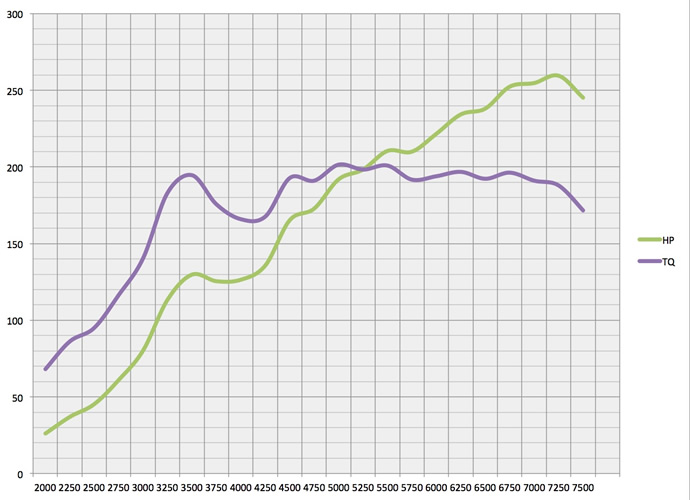

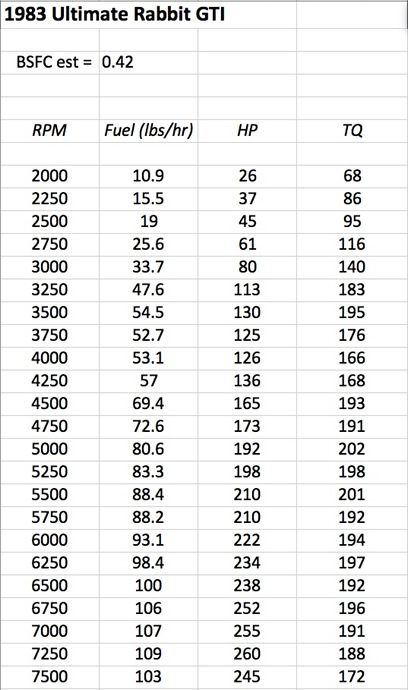

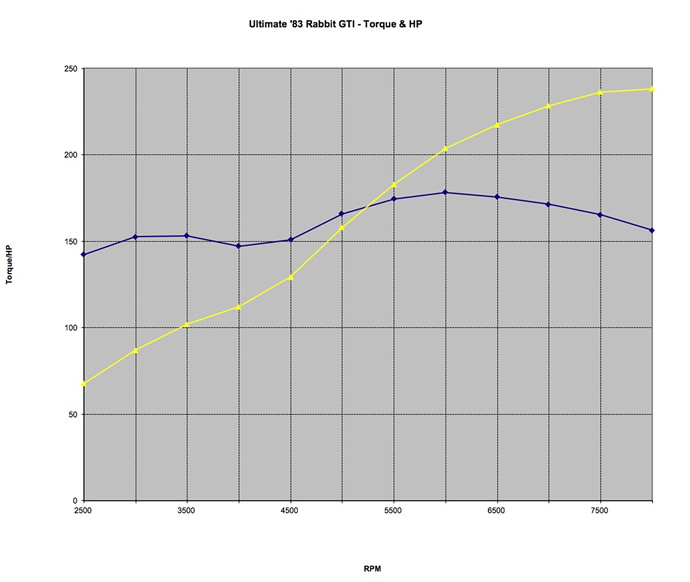

I confirmed a number of basic performance parameters via a series of full throttle acceleration runs and some hard cornering and slaloming dynamic tests: There is practically zero body roll with this suspension system and there is tons of grip but the car is not overly stiff/harsh except on rough concrete expansion joints where the car bounces around with its short wheel base. The estimated 0-60mph time seems around 4s but the tires can't hold the power in 1st gear at any RPM >3,500 so I won't know the true potential until I bolt the slicks on at the track. The computer has provided fuel data which allows me to estimate power and torque #s by using BSFC (for a street engine 0.5lbs/hp-hr of fuel consumption is reasonable but highly tuned race engines such as mine are more efficient at around 0.42lbs/hp-hr). At 0.42 BSFC my engine is putting out 260hp @ 7,250rpm and 200 ft-lbs of torque from 4,500-7,000rpm which is quite something. Obviously this needs to be backed up with dyno pulls, g-meter acceleration data, and track 1/4 mile racing results. I'll have the g-meter acceleration data in a few weeks. [see update below - this was estimating hp from the top rows of the fuel table at 101-102MPa - in practice the engine only sees 99MPa so power is actually 240hp, not 260hp]

The engine exhaust smells more than I think it should and the oily black soot in the exhaust pipe indicates that the rings have not fully seated yet. I took out the spark plugs and they are absolutely clean looking on the electrical contacts but the metal base rings are a bit oily. I also used a computer/USB microscope to look into the combustion chambers and inspect the pistons, block cylinder walls, and valves - I saw cross-hatching marks still on the cylinder walls which look evenly shiny 360 degrees around, but the edges of the combustion chambers were a little oily looking, with one cylinder actually showing a small drop of oil on the wall, plus the piston crowns looked a little fouled in spots and also a bit wet in spots from oil. The question I now have for engine builders is: how long should it take for my rings to seal (I only have about 4-5 hours of real engine running time where I have been driving the car and less than 10 full throttle acceleration runs to attempt to fully seat these racing rings)? Is there a problem with my rings not seating? I have been using Joe Gibbs Driven Racing Oil 00106 BR 15W-50 Break-In Motor Oil.

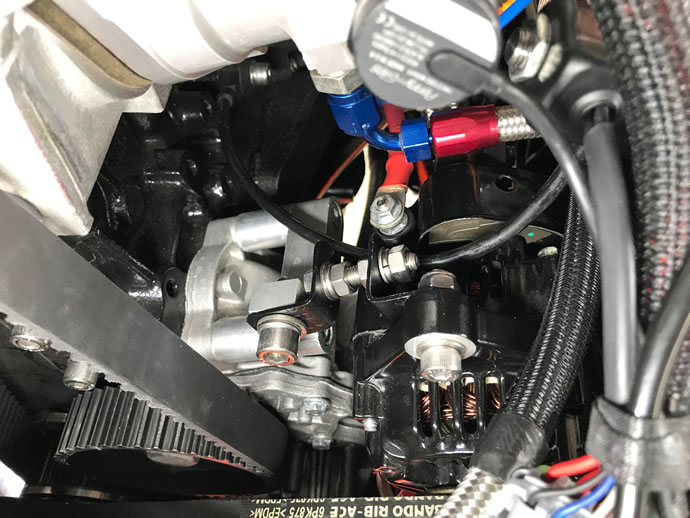

After my 3hr drive I realized that my new mini Denso alternator was burned out/DOA. It could have been my ECU control circuit which tricks the alternator into limiting its output voltage to 13.8V (for my LiFePO4 battery) by providing 14.6V into the Vsense input when the output reaches 13.8V. Anyway, I have ordered a PowerMaster 8188 XS Volt 75 Amp mini Denso alternator from Summit Racing with expedited shipping - this unit has fully adjustable output voltage capabilities plus an input that when grounded will reduce the output voltage 1.25V to cut the power draw from the engine by over 50% - saving a few hp during WOT acceleration runs - October 30, 2016

Power estimate from the ECU fuel tables - estimated about 20hp too high due to the use of 101-102MPa MAP values rather than 99MPa where the engine actually operates - see below ...

I changed the oil (another fill of the break-in oil) at 300kms and will finally switch over to full synthetic oil at the 600-800kms point. It is likely just in my head but I think the engine runs better with the fresh oil in it.

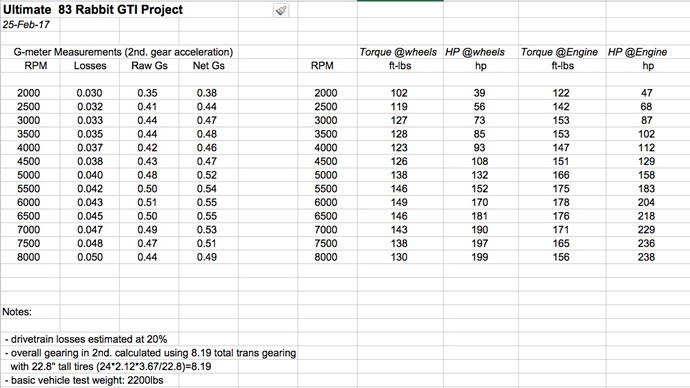

I did a total of 6 acceleration runs with my new accelerometer and consistently saw over 0.5g of raw acceleration from 5,000-8,000rpm in 2nd gear which is quite something considering that I have the longer final drive ratio gearing installed in the transmission (I can reach almost 120kph/70mph in 2nd gear), so that means I am pulling with about 25% more Gs at 70mph than my old '87 Mustang did with its 340hp engine at 40mph. The GTI feels very alive above 5,000rpm and in fact it feels a little dangerous/unstable - you simply don't want to put your foot all the way into it unless the road is straight and smooth as the car will start to dance around and head into the rubarb if you aren't totally in control of things - you need to hold on to that steering wheel and keep things heading in the right direction. Heaven knows how I am going to handle another 100hp of nitrous on top of this.

It is very easy to convert acceleration data into torque and hp - you just need to know the actual weight of the car and the rpm and wheel diameter and you have a direct measurement of the power being produced at the wheels. You need to perform a coast-down test to determine the losses due to wind resistance and rolling losses and that is all. I have confirmed 200hp at the wheels at 7,500-8,000rpm and 150ft-lbs of torque at 6,000rpm. Using the commonly accepted 20% drivetrain loss estimate for manual transmission cars that is 240hp and 178ft-lbs of torque for a 2.1L normally aspirated engine which actually idles like a stock engine at 1000rpm - that is a rare experience (for cars without computer adjustable cam profiles). I realize now that the above hp calcs from October 2016 were based on the Holley ECU fuel flow tables at 101MPa of vacuum were over-estimating the hp simply because my MAP signal is actually only 99MPa at full throttle, not 101MPa so I never get to the absolute top of the fuel tables in practise ...

Oh, and I just ordered some Sparco EVO racing seats and 4 point racing belts to keep me safe and secure while being tossed around at the track - the stock GTI seats are a bit wobbly and don't really have the aggressive racing-type side bolsters to keep me firmly locked in place and in total control of this wild hare. I'll use the stock seat belt mounting points to fabricate and install a mini roll-bar and seat/seat-belt brace structure, plus I have ordered a pair of GTI seat frames to allow me to fabricate mounts for these Sparco seats that will simply attach to the stock seat h/w in the floor.

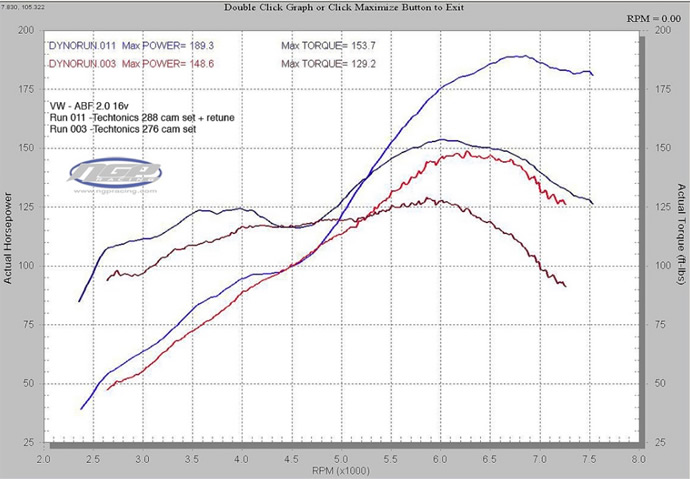

I have included the wheel hp/torque measurements for a similar 2 litre ABF motor with the same Techtonics 288 race cams and similar heads and compression, but with the OEM log-style intake system below. It achieved the same torque at the same rpm but ran out of high-end breathing due to the intake manifold, where-as my ITBs allow power to keep building past 8,000rpm. ITBs and careful ECU programming also allow my engine to idle and have excellent part throttle/low rpm drive-ability where-as this other car barely idles and has terrible sounding part throttle response:

http://forums.vwvortex.com/showthread.php?5078261-189whp-153wtq-2.0l-16v-ABF-Info-inside

288 cam, 11.5cr 2L ABF motor with common intake plenum on the rollers at NGP

http://www.youtube.com/watch?v=1YeZNElfsNo

288 cam, 11.5cr 2L ABF motor with common intake plenum at startup and idle

http://www.youtube.com/watch?v=VILRqAkv24I

- February 27, 20167

My accleration and power measurements ...

Reference check: 288 cam, 11.5cr 2L ABF motor with common intake plenum on the rollers at NGP ...

The racing seats I just ordered for track and high performance driving needs ...

I made the decision to be safe on the race track with Italian Sparco racing seats that will hold me securely in place for improved driving accuracy, equipped with 5 point harnesses to keep me safe if something bad happens (note, I am going to attempt to use a Simpson single anti-submarine lower belt rather than the dual belt Sparco design as I think they are cross-compatible with both cam-lock systems). I received my new racing Sparco EVO seats which are really nice and started the process of cutting up some OEM seat bases to use as a foundation for a 1x1" square tube mounting base for the seats - the idea is to have the convenience of the stock mounting locations and fore-aft adjustability. I am also fabricating a cross-tube to mount the shoulder belts to that will attach to the upper and lower frame bosses for the OEM seat belts. I will likely race with just the driver seat installed - no passenger or rear seats for weight reduction purposes (unless I am showing off and having a passenger on the track which will happen from time to time). I am also fabricating a horizontal extension plate for the shifter as it is too far forward to reach comfortably when held in place by a 5 point harness - March 20, 2017

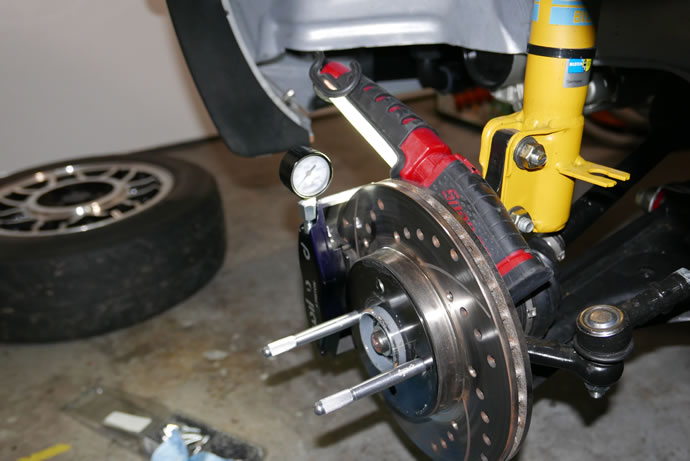

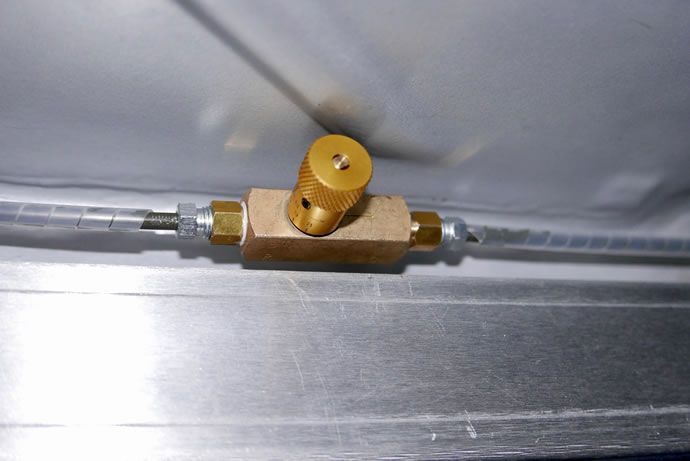

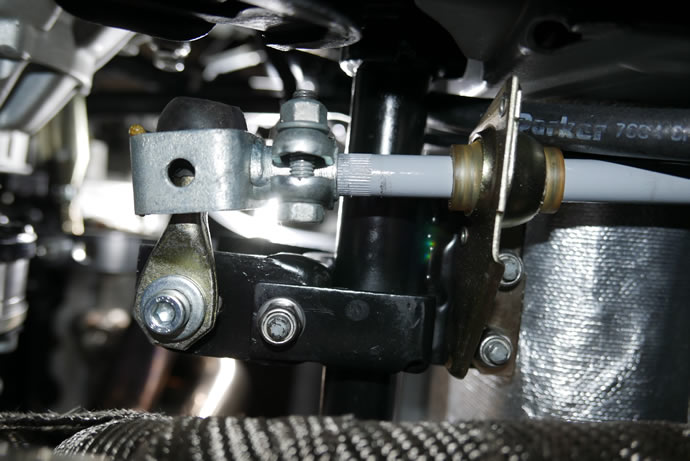

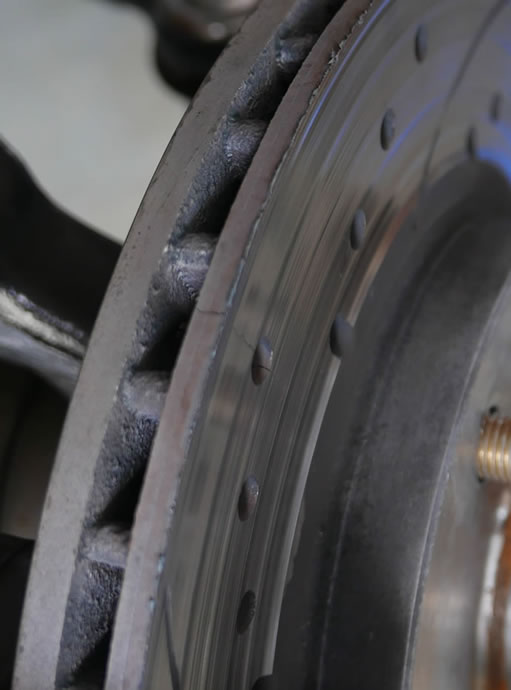

I have been fooling around with my braking system, trying to set my rear brake line pressure to the correct level to avoid rear-first lockup conditions without success, and it didn't make any sense to me as I have a Wilwood adjustable proportioning valve in the system. I also wanted to explore ways to continue to improve the responsiveness of the brake pedal - to have it activate as quickly as possible with the minimum brake pedal travel, so I also sourced a 25.4mm master cylinder to swap in replacement of my current 22.2mm MC. This would have the net effect of reducing pedal travel 30% while increasing pedal effort by the same ratio, and since I already prefer running my brake servo vacuum at 50-70% of maximum available vac I can do the swap and maintain the same pedal effort by simply turning up the vacuum (I have an electric vac pump under ECU software control so this is easy to adjust on the fly in the car - I have a panel dial that I can simply turn).

Anyway, I sourced a 3,000psi line pressure gauge with the appropriate adapter fittings to screw into the blanked-off MC ports front/rear and also the bleeder valve ports on the front and rear disk callipers. I first tested the MC and both circuits showed 750psi without servo vac and 1500-1600psi with max vac. Note, I have a custom brake line setup with 1 circuit to the front and another to the rear to accommodate my proportioning valve - similar to many US spec cars.

Next I tested the line pressures at the front callipers and again saw the same 750-1,500psi range. Finally on the rears I saw 500psi at minimum prop valve setting and 1,500psi at full prop valve setting - the surprise was that I realized I had been turning the prop valve in the wrong direction when doing panic brake stop tests.

By reference the factory test settings for VW mk1-mk4 cars is around 1,500psi max for the fronts and 510psi for drum rears and a bit less (around 490psi) for rear disks, depending on the car. The front/rear bias ratio will depend on a lot of factors - the weight bias of the car front/rear, most importantly while under panic braking, and then the type of front and rear callipers or drums - how much fluid volume is required to move the pistons - the piston area x # of pistons will determine the total force applied to the rotors.

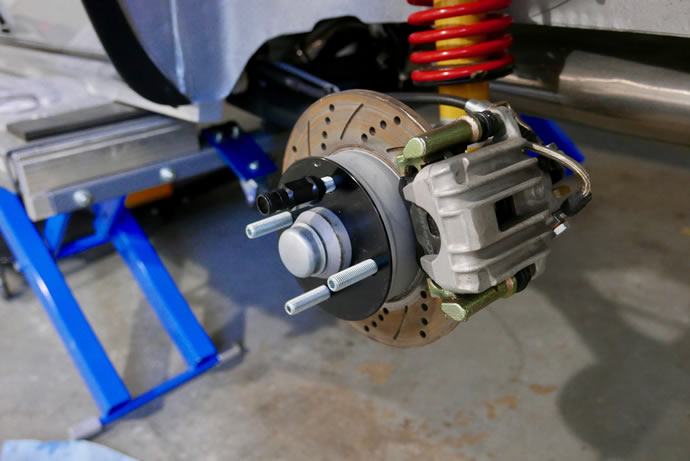

In my case I have upgraded to Wilwood 4 piston callipers so the volume of fluid that needs to be moved to get to maximum braking pressure is much higher than for a stock single piston calliper. I didn't do all of the calculations but I think that the 22.2mm MC is a bit small for the Wilwoods and also that the rear bias needs to be fairly low, in the 550psi range.

I'll wait for the ice and snow to melt (Hopefully later in January) and will get back out for some more panic stops with the current 22.2mm MC before swapping it out for the 25.4mm MC - January 2, 2017

After doing some more reading about the Wilwood proportioning valves I now understand that when they state 100-1000psi adjustment range they are not telling the whole story - their valves can only reduce the rear brake pressure to 57% of the fronts so if the fronts are 1000psi the rears will be 570psi. I did measure around 500-550psi at the rears during the testing above with the line pressure gauges installed but with the extreme front weight bias of my FWD GTI and my grippy rear disks/pads I may need to go lower still - as low as 400psi, so I have sourced a really tiny and cool little prop valve that can lower the pressure all the way to zero if needed and I will put it inline with the rear circuit so I can reduce the pressure even more if I need to. Once I go to the effort of swapping in the 25.4mm master cylinder I don't want to have to re-bleed the brakes yet again if I still experience rear lock-up ... better to take this additional step now while everything is apart - February 7, 2017

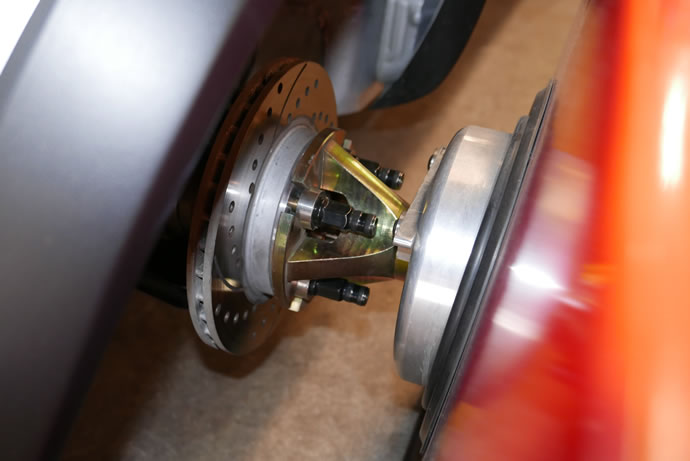

Josh had proudly sourced some OEM German axle assemblies for me but I found that they had some free-play in them which resulted in a bit of 'slap' when going on/off the throttle as that slack was taken up. Rotating the wheels about 1/4" was the total amount of movement but it was enough to make driving a bit annoying at times when feathering the throttle in city traffic. One theory is that I was using the brakes to load the engine when it was initially fired up on jack stands and the axles weren't totally level, causing the power to be transmitted thru the CV joints at an angle - that may have stressed them and worn them? Anyway, I ordered some expensive 500hp rated racing axle assemblies from The Driveshaft Shop in NC and they are superb quality, using CVs that are 40% larger with all components upgraded end to end. There is no free-play in these assemblies so I look forward to installing them soon - February 7, 2017

I finished the installation of the 3-axis accelerometer in the car and then did a fine tuning of the calibration in software on the ECU such that the sensors now read accurately to less than +/-0.005g for acceleration, and around +/-0.01-0.02g for braking and corning. I still need to confirm that vibration and electrical noise from the ignition system won't reducing the accuracy, but if noise is added to the signal I can always run a smoothing function in the ECU diagnostics and effectively cut out the noise.

I installed the 25.4mm master cylinder and adjusted the brake pedal linkage, adding back one spacer (for a total of 2) between the servo and MC, and setting the pedal position such that the MC engages immediately within the first 1/10" of foot pedal travel. I also installed the mini proportioning valve in series with the existing Wilwood prop valve and then ran system brake pressure tests. It turns out that I had originally installed and set the Wilwood prop valve correctly as re-testing this weekend proved that even when set at the minimum setting, about 550-600psi of rear pressure is still present when the front pressure is 1000-1500psi (which explains why I was experiencing rear lockup).

With the 25.4mm MC replacing the 22.2mm MC, the brake pedal travel is indeed 30% shorter and the force required to stop at a given rate is also 30% higher as expected. The reason for swapping MCs was done mainly to avoid having the pedal travel too far, making heal-and-toe braking into corners for downshifting purposes almost impossible - too much pedal travel puts the right foot at a sharp angle to the throttle making it way too easy to excessively rev the engine. Having 4 piston callipers up front takes more fluid volume to operate, causing the MC piston to travel further, etc., hence the preference for the new 25.4mm MC. And since I had previously decided that I liked less servo vacuum for a firmer pedal feel, all I needed to do to get back to the same pedal feel was to turn up the servo vac 30% and all is well.

The new mini prop valve (Deltrol p/n 10120-40, Speedway p/n 910-31357) allows the rear pressure to be reduced all the way to zero if desired (for RWD burnout competitions this is what people want) so I was sure it would help me with my problem and it did work as expected. With the valve 80% turn off I got to a max pressure of 500psi and it ramps to that pressure over approx 1s so it has a damping effect on the rear pressure when the pedal is pressed which is actually not a terrible thing - if the prop valve is adjusted to the threshold of rear lockup this will soften the effect and reduce the tendency for a sudden change in direction (i.e. the rear of the car swinging wildly around to the front).

I also installed Wilwood E type pads on the front which have about 20% higher coefficient of friction than the previous BP10 type pads - so once they are warmed up to around 250-300 degrees F the fronts will have more braking sensitively than before which may allow me to adjust the rear pressure up higher. When I am doing lots of track laps I will switch to BP20 pads which have the greatest coefficient of friction at temperatures above 800-1000 degrees F and again, I may be able to dial up the rear pressure more again. The idea is to have the rear brakes do as much work as possible to off-load the work the fronts have to do.

I will be switching to the new front racing axles soon which require extended length racing type studs so I went ahead and installed extended length studs in the rear allong with the new Gorilla open backed 'tuner' nuts which are required when running extended length studs - I also had to use conical to ball seat adapters as the 'tuner' nuts are not generally available with conical seats - and I already have to run conical h/w for my Enkie/Hoosier racing wheels and slicks. I think they look decent enough on the OEM VW Snowflakes and they sure are a lot easier to mount/dismount than the OEM bolt system too.

The snow and salt should be washed away by rain over the next week and I may then have a chance to do some road testing to confirm that I didn't add too many spacers between the servo and MC (last time I had 3 spacers and after a few minutes of driving the car started to self brake - likely caused by the brake system warming up and expanding a bit (my tolerances were too tight/aggressive) - February 13, 2017

I got the OEM axles pulled out and installed the new 500hp rated axles but it was a ton of work: first the spindles/hubs needed to be pulled apart so the new hubs (larger splines and shaft, 32mm nuts, etc.) could be pressed in with fresh bearings, then I over-extended the axle angles when installing them and had to re-build the inner CV joint on one side as the ball bearings had fallen out, then the inner cer-clip on one side was binding against the axle so it all had to pulled out yet again, and finally it all went back together successfully.

After driving around with the new axles I can say that they definitely have tighter tolerances so all I am now left with is a bit of that on-off-on throttle free play from the limited slip diferential that I will simply have to live with - it is only noticeable during slow city driving in heavy traffic. That diff also whines a bit in comparison to the OEM unit - but I don't really notice the increase in mechanical noise much.

The new 25.4mm master cylinder setup feels great - more pedal effort required but the pedal travel is now minimal so heel-and-toe downshifting will be much easier to do - and I simply like a stiffer brake pedal anyways. I just crank up the electric ECU controlled servo vacuum when I want an easier braking effort. The 2nd in-line proportioning valve has indeed solved my front-rear brake balance problem. Panic stops result in straight line skids now. I will wait for warmer weather with cleaner streets before fine tuning the balance setting (too much salt and sand dust still on the roads).

I did have to back off somewhat on my brake pedal preload - I have a custom linkage that allows me to set the servo/MC preload to reduce pedal travel but I was at the point where there was a bit of self braking once the system was fully warmed up - backing off the brake pedal 1/4" solved that problem and now there is a softer initial brake response for the first 1/4-1/2" of travel which is actually a good thing. I am very happy with the end result - February 27, 2017

After further thought I have decided to purchase the unique Tech-53 callipers (made specifically for Tech-53 by Wilwood) and replace my standard-issue Wilwood Powerlites as the Tech-53s have 68% larger piston area, which will vasty increase my stopping power relative to brake pedal force, and more importantly will improve my front/rear circuit bias such that I can run without the 2nd proportioning valve.

After a long discussion with Fred, the owner of Tech-53, about my brake bias issues, pedal pressure requirements for a panic stop, etc. it became very clear that my Wilwood PowerLite 4x1.25" piston callipers were undersized relative to the task at hand - in fact they are only 15% larger in total area than the stock single piston callipers so they don't effectively shift enough of the brake bias forward to avoid premature rear wheel lockup.

Fred is an aerospace engineer who has put in a lot of time into thinking about the lack of properly spec'd 4 piston callipers that are available for mk1 and mk2 cars so he went about negotiating a deal with Wilwood to have some large piston callipers custom made to his specs. They use 1.625" diameter pistons vs the 1.25" diameter pistons in my Wilwood Powerlite callipers, thereby providing 68% more clamping pressure (and therefore braking torque) - and that means that for a given brake pedal pressure the car will stop 68% faster - up to the limit of the tires, with minimal increase in pedal travel. Since I have a huge, race oriented 25.4mm master cylinder, pedal travel and feel will not be negatively impacted. Fred says the 23.8mm MCs are an ideal street match to his callipers and that 25.4mm MCs are awesome on the track - since I like a stiff brake pedal I am pretty sure I'll like the feel on the street as well, given that I am already pretty happy with the way my existing system feels.

Fred also pointed out that the G4 rear aluminum callipers are 2mm larger than the steel G1-3 callipers (38 vs 36mm) so that aggravates the premature rear lockup issue. I am confident that I will be able to eliminate my 2nd proportioning valve now and also be able to dial back the Wilwood valve to reduce the time delay effect in rear circuit pressure build-up.

I have completed a brake conversion table with all of the common after market setups (brake torque, front-rear bias, etc.).

My excel spreadsheet analysis can be found here: http://www.derekspratt.com/Misc/VW_Mk1_Big_Brake_Conversion_Analysis.xlsx

- March 7, 2017

We still have winter conditions in the Pacific Northwest for the most part, but there are the occasional days when the sun is out and temperatures are up enough to do some driving/testing. The roads still have a lot of sand on them so traction is limited and the sand gets into the brake system as well ...

My first attempt at driving around the block with the new big piston Tech-53 callipers was cut short by some nasty sounds coming from the front wheel area. I had obviously checked the clearances so I was puzzled about what the sounds were. My inspection found that the control arm ball joints were lose - the 'grade 8.8' bolts were actually stripped and so the ball-joints were barely being held in place. Yikes! It turns out that the crap bolts were imported junk and are now being replaced with OEM/German grade 10.9 h/w. Double-check the h/w on any aftermarket control arm/ball joint combination products that you may purchase ...

Another area where cornering noise was coming from was due to the new CV boots sticking/rubbing each of the folds against each other - by 'lubricating' them with rubber care treatment they became quiet as well. Finally, sand was getting into the brakes causing some intermittent scraping sounds (I don't use OEM dust shields to help cool the rotors on the track).

With all of those gremlins out of the way I was able to do some braking tests: the Tech-53s take about 1" more travel, which makes sense, as the volume of fluid required to push those big pistons is greater, but the force required is a lot less, making the brakes feel very responsive and powerful, which is what I was hoping for. I will look into adjusting the brake pedal linkage again, putting a bit of pre-load on the system - and double-checking that I am not over doing it as in prior attempts to reduce pedal travel. With the large 25.4mm master cylinder paired to these Tech-53 callipers the pedal feel and travel are close to ideal now. The biggest area of improvement comes from re-balancing the front/rear braking bias - I have now fully opened up the 2nd proportioning valve and panic stops in the rain did not cause pre-mature rear wheel lockup so all is well. I will start to back off the reduction setting in the main Wilwood proportioning valve next ...

I need more time to drive in dry conditions, which I should be getting by the end of the weekend so stay tuned for more commentary on this new braking system. I am all smiles for now - March 13, 2017

After tracking down the grinding noises from the front end while testing the system I noticed that the clearance from the outside edge of the rotor to the inside surface of the calliper was minimal on the driver side and there was evidence of some minor contact. I was able to loosen and move the calliper to gain more clearance but decided that for racing thermal expansion purposes that I would increase the gap from 0.020" to 0.070" by milling the rotor down from 10.1" to 10.0" - this still left enough surface area for 100% brake pad contact so there will be no reduction in braking performance. I also had some minor contact between the outside edges of the callipers and the inside surfaces of the 14x6" OEM Snowflake wheels so I have swapped out the 3mm spacers for 5mm spacers.

After bedding the new pads the brake feel from this new Tech-53 big 4 piston calliper system is incredible. I did some brake pedal linkage adjustments such that the pads contact the rotors when there is less than 1/4" of pedal travel so the brakes are now very responsive. I believe that these callipers are a huge advance in mk1/mk2 brake performance/feel and certainly address the prior issue of front/rear system bias - I have not backed off the proportioning valve but will do so later today and do some more testing. Even with the valve at its current setting the car stops urgently with only moderate brake pedal pressure. I also think that the 25.4mm master cylinder is an ideal match to these Tech-53 callipers.

With the prop valve backed off 2 full turns I was able to get all 4 tires to enter a skid condition together at the same time. Max braking deceleration was almost 1.1g with the street R-compound Bridgestone Direzza-II 185/60-14 tires (when the air and road temperatures were only 50 degrees F) so this little bunny is stopping with the best of them now! - March 20, 2017

I had been struggling with poor shifter feel/engagement into 1st gear and so I set about disassembling the shift linkage in order to step-by-step find out where the problem area was. The transmission selector lever itself had a nice positive feel and clean engagement of each gear but I found that something in the linkage was resisting full movement into the 1/3/5 gear positions. It turned out that the rubber ball lever end wasn't moving smoothly and upon closer inspection I could see that the metal rod portion of the rubber ball lever was binding on the metal bracket that it is inserted into - and this was caused by the shifter rod being at the wrong angle as it entered the positioning bushing/bracket. So I pulled the shifter rod out of the car and bent it about 7 degrees about 8" back from the end and it was then perfectly parallel to the black mounting bracket assembly and positioned the metal bracket right in the middle of the rubber lever arm. I was worried that my 0.040" metal shim inside the metal bracket was causing binding with the rubber ball but once everything was aligned properly and greased up, the rubber ball rotated smoothly and didn't bind at all. With a 1/2" lengthening of the upper ball-joint arms to re-align with the new setup, everything was tested and then re-torqued into place. The result is 100% improved shifter feel and perfectly positive engagement in every gear. I am in shifter heaven now)- March 21, 2017

The shift rod before it was bent to be parallel to the black bracket assembly - you can see that the rubber ball isn't centered - causing binding and travel limiting of the 1/3/5 gear positions ...

I finished the fabrication of the seat mounts for the new Sparco EVO racing seats using the mounting flanges and legs from a junker set of OEM seats - they worked out very well - a little lower position than the stock seats and full adjustability of fore/aft position using the OEM mechanism and slope using some bolting options with the Sparco mounting flanges. Should be sweet!

I don't have a tube bender so Ted at JetFab in Richmond, BC will be fabricating the bolt-in roll hoop which will use the stock seat belt mounting points to secure it to the body of the car. The hoop will have the cross-bar for the shoulder harness mounting points plus a central camera mount. When it is complete I will send the seats and hoop out for powder coating.

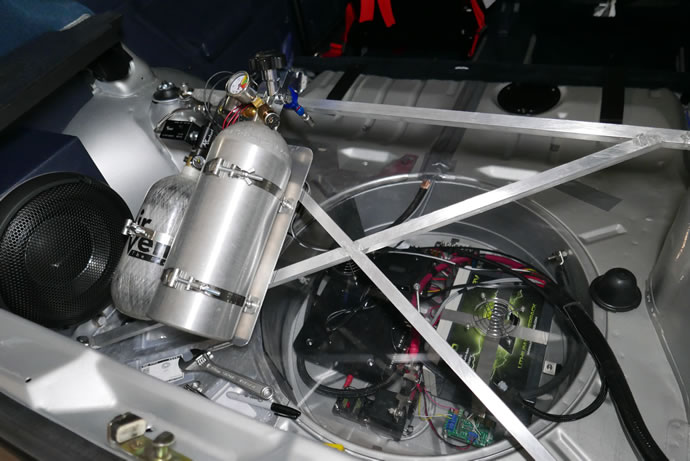

I am also fabricating a rear shock tower cross-brace that also connects into the rear bumper mounts which will be needed as a mounting location for the nitrous and air tanks (the 4500psi air tank pressurizes the nitrous bottle to 925psi and holds it exactly at 925psi using a regulator rather than relying on a heater which doesn't keep the nitrous pressure constant while it discharges). I don't think the brace will actually have much effect on stiffening the chassis further as it is already welded up with a sub-frame, cross-bracing and will soon have the roll-bar ...

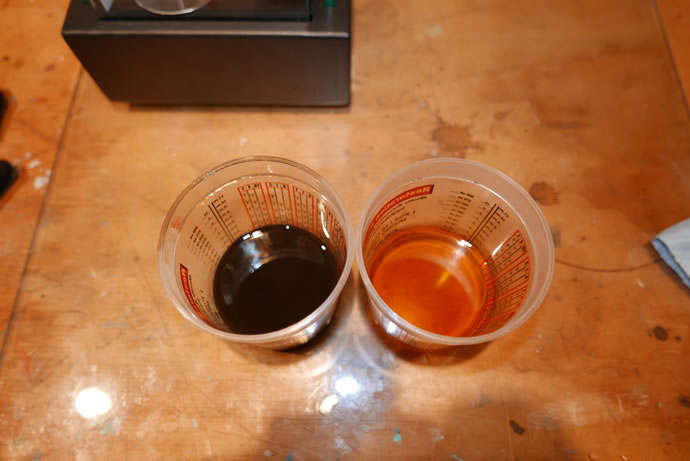

I was complaining about the Walbro 393 fuel pump making a nasty noise so I talked with Kinsler Injection which supplied me the whole fuel injection system and most of the engine sensors, wiring harnesses, etc. and they said 'check your 25 micron intake and 10 micron output filters' so I did and found the intake filter completely plugged up with a nasty black sludge which looked like jello! The intake filter is a steel mesh so I cleaned it while I replaced the 10 micron paper filter and also replaced the pump as it had been damaged from the stress of pumping against such a massive restriction. The black sludge could simply be from old gas sitting in the tank for months at a time (if that is true it is actually from bacteria which is always present in fuel, more in ethanol enhanced fuels which also are hydroscopic and suck up water). There is also the possibility that my dumb attempts to seal-up my old fuel tank level sender with silicon sealant (since replaced with a new sender and o-ring) may have caused this as the silicon dissolved in the fuel. Anyway, I will keep an eye on this issue and service the fuel system filters more often. Next time I will do this when the tank is almost empty, rather than completely full! It would have been smart to have installed a fuel tank line valve too - I rely on hose-end plugs to service the fuel system.

Finally, I have put 1100kms of mountain driving on the GTI so far with 700kms of that this last week alone - 3 days of driving to Whistler, with 25,000' of total vertical climbing. I switched out the Joe Gibbs break-in oil now for their 10-30W hotrod conventional oil which contains lots of ZDDP zinc to protect my solid lifter cams/tappets which are under extreme pressure from 8,000rpm and high lift racing cams and springs. I will switch again to their 20-50W oil when I get to the track in May. I may eventually switch to their synthetic oil with ZDDP added to it after 5,000kms. When decelerating from 5,000rpm the MAP signal drops to 17MPa which is the equivalent of 25" of mercury vacuum so the rings on the pistons have sealed nicely - April 2, 2017

For over 30 years now I have been measuring vehicle performance using accelerometers and then using either my own programming or off-the-shelf software programs to further analyze and predict performance, helping to choose rpm shift points, gear ratios, wheel and tire combinations, etc.

For this project I again used accelerometer measurements, along with fuel flow data from the Holley ECU to confirm the engine torque and hp curves and I loaded that data into Excel and added nitrous in varying amounts to see what kinds of torque/hp curves could result and then fed that data into a drag racing simulator, Drag Racing Pro v2.0, and adjusted all of the vehicle and driving info to produce realistic 0-60mph and 1/4 mile charts and graphs, using my newly acquired Hoosier 225/50-15 DR2 drag radials on 15x8" rims, using my excel data. The results are as follow:

Engine only (no nitrous): 0-60mph 4.1s, 1/4 mile: 12.3s @ 112mph

Variable nitrous to produce a flat 200 ft-lbs torque curve: 0-60mph 3.8s, 1/4 mile: 11.8s @ 117mph

60hp nitrous at all times: 0-60mph 3.5s, 1/4 mile: 11.5s @ 120mph

80hp nitrous at all times: 0-60mph 3.4s, 1/4 mile: 11.3s @ 123mph

The simulator shows that a FWD car like the mk1 golf is severely traction limited due to the weight on the driving wheels being only 50% during acceleration, vs a RWD car that would have 80+%. So even with slicks and a solid trans mount and stiff springs the best I can hope for is a 1.9s 60' time and a little over 0.81g of acceleration in 1st gear.

I already know that 1st gear on the motor alone with sticky street tires is a 50-60% throttle gear, but with nitrous even 2nd gear with slicks becomes a problem. It will be fun to get the car on the track soon and find out (May 12th is the 1st local track 'test and tune' day that I will be ready for).

Ted/Jetfab has the roll-bar finished now so it is out for powder coating. Seat mounts are done too so all safety gear that I want to have for track days is now 'good to go'.

New video here: https://youtu.be/6s9wYpSIfik - April 12, 2017

I sourced Hoosier 225/50-15 DR2 slicks and mounted them on Enkei 15x8 RP1 racing rims and used 10mm spacers to clearance the struts - if I hadn't lowered the car so much they would have fit perfectly but in my case I have also sourced 1" rubber spring spacers to lift up the front end and provide more of a fender gap.

I also sourced a solid rear transmission mount which is something a lot of VW mk1 drag racers have recommended - it keeps the engine from rocking back and forth, improving traction on the track.

I have sourced the required components to get a brake cooling/ducting system put together - something I will get done before heading out for a road course track day ...

On the electronics side of things I have put together a full video recording system using the 'Harry's Lap timer' App on my iPhone, plus a high frequency bluetooth GPS, a bluetooth OBD/Canbus transmitter, and a Hero4 GoPro - mounted to the middle of my new rollbar - this will allow me to record HD racing videos complete with embedded track location/performance data.

I got my shifter extension built and love it ...

My rollbar was powder painted and installed, and I also mounted one of the Sparco EVO seats to my new seat frames and installed the harnesses - it all looks so 'trick' now with the other seats removed.

I fabricated an aluminum 'X' brace for the rear of the car which holds everything in position for road racing and also works nicely as an angled mount for the nitrous and air bottles - it still needs to be painted though.

This Friday is the local Mission RaceWay 'test and tune' day but the weather does not look promising. Possibly later in the day the track might dry out but I am not sure it will be worth the cost and effort to go out and sit there watching the rain come down, waiting, waiting for the track to dry out (something I have done many times) - It may be May 26th for the next T&T day :(

Finally, I cleaned out the intake fuel filter again and found some more of the black gunk in it - I still believe it is the remaining crap from the silicon sealant I had previously used to seal up the fuel sender - I will check the filter again in another month. I also purchased a combustable fuel vapour sniffer and used it to confirm that my stainless fuel lines are releasing vapours - and this has been confirmed by the manufacturers of stainless/rubber lines - they don't fully keep the fuel sealed up and cause a slight odor. Strange as I think that is a bad design/material spec. I will likely rip out all of the fuel lines and replace with stainless/teflon lines at some point down the road as I don't like my GTI smelling like gasoline when I go into the garage - May 9, 2017

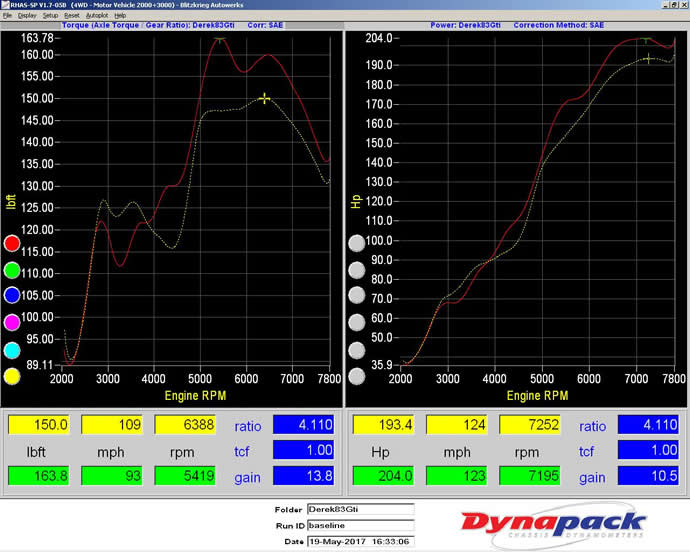

I spent a few hours at Blitzkrieg Automotive in Vancouver today with the GTI axle-bolted to their Dynapack dyno today and it was really a fun and worthwhile experience. The traditional roller-type chassis dynos have some potential variables with rolling friction that can vary depending on how tightly the car is held down onto the rollers while the Dynapack unit not only removes this variable (and any tire slip) but also securely holds the car in place without risks. The units are super expensive ($150,000) but their accuracy and repeatability are 1st rate. I was able to look for 1 and 2hp improvements over a range of parameters and slowly find missing power. We did about a dozen pulls covering fuel/air ratios, timing, injector end angle (the point in time when the injectors stop firing relative to the compression stroke), removal of the air box and filter and replacing the long intake trumpets with shorter trumpets. We were also going to test the nitrous system but the nitrous ECU enable line wasn't triggering the system properly so I will have to do this at the track and on the road next week (I found the problem later - Holley has a naming convention bug with the nitrous enable input that I had to work around by creating a touch-screen 'master nitrous enable' and then a ''stage 1 enable' using my dash mounted switch - I am pretty sure it will work now). Here are the test results:

191 hp @ 7200 rpm, 150 ft-lbs @ 6100 rpm - 13.0:1 A/F ratio, 26 degrees of total timing

192 hp / 151 ft-lbs - 13.2:1 A/F

194 hp / 151 ft-lbs - 13.4:1 A/F (13.6 saw a drop in power so this is the ideal A/F)

196 hp / 150 ft-lbs - 28 degrees of timing

197 hp / 150 ft-lbs - 30 degrees of timing

198hp / 150 ft-lbs - 32 degrees of timing (I did not attempt to advance the timing any further)

198hp @ 7200 rpm, / 162 ft-lbs @ 5400 rpm - no air box or filter

204 hp @ 7200 rpm / 164 ft-lbs @ 5400rpm - shorter intake runners/trumpets

Leaving the injector end angle at 0 degrees (start of compression stroke) was the default ECU setting and made the most power.

The big story was the removal of the air box and air filter - it increased the engine torque dramatically over a wide area from 5000-7000rpm and moved the torque peak down 1000 rpm - this will improve the overall acceleration 'area under the curve'. On the street it isn't practical to run unfiltered air into the engine (it will ruin it over the long haul) plus the noise from the ITBs is massive - you can hear the engine accelerating 10 blocks away with the air box removed - it is much louder than the exhaust system.

Dynapack dynos are reliable and conservative power measuring devices - to calculate crankshaft power add back the estimated 15% loss which brings this engine to 240hp which agrees exactly with my accelerometer testing last month so I will simply use my accelerometer testing for the nitrous system benchmarking next week. FYI, my 2L GTI engine produced the most power these guys have ever measured on this dyno of this size and type of motor - no other 2L 16V NA engine has exceeded 200hp before so they told me I have a 'sick' motor ... - May 19, 2017

Plots comparing pull #2 vs the final pull with all of the improvements in ECU programming complete ...

click here for a full-size image

[Special thanks to Kevin Young, a fellow vw mk1 enthusiast, for helping me out at the track all day - it would have been very difficult without his assistance]

I drove the GTI out to Mission Raceway last Friday and bolted on the Hoosier DR2 225/50-15 slicks with 10mm spacers and 1" rubber coil spacers to give me barely 1/2" of needed clearance to the wheel wells - and they didn't rub even after lowering to 15psi and doing 5 passes on the strip. Yeah!

The s/w simulator, when loaded with the dyno test results, indicated that when fully dialed in the GTI should get close to 12.3s @ 112mph w/o nitrous, and around 11.5s @ 123mph with 80hp of nitrous. I ran 13.8s @ 104mph. What happened? Lots. I'll be back again on June 16th, weather permitting, which is the next 'test and tune' track date.

Lessons learned from day 1 at the track:

1. I need to increase the rev limiter from 8000 to 8300rpm (I was hitting the rev limiter in each gear for 0.25s before shifting)

2. Install that solid transmission mount to stop the wheels from loading/unloading all the way thru 1st gear

3. Do a bigger ‘proper’ burnout after going thru the water box as the tires were still wet and not gripping properly – drive thru the box and start the burnout on the other side, keep them spinning until there is some smoke

The total damage relative to my software simulated runs...

I ran a 2.3s 60' time rather than a best possible 1.8-1.9s time (0.4s delta) - looking at the ECU datalog it is clear that I wasn't even at 50% throttle for most of 1st gear - and the tires were still spinning like mad, plus the time from throttle off in 1st and back on in 2nd was over 1s ... this kills ET and mph as the car is eating up track distance without any acceleration - I needed only another 30' of track to reach 8000rpm in 3rd which is 111mph with the larger diameter slicks ...

I shifted too slowly each time (0.5s lost total), I hit the rev limiter for about 0.25s in each gear

I ran 13.8s @ 104mph and it is easy to see that the GTI indeed has the potential for mid 12s 110mph+ time slips on the motor alone ... I need more seat time at the track for sure - this isn't as easy as going to a chassis dyno (it requires skill that I currently lack). Hmm.

And the nitrous wasn't working - I will need to debug the wiring to the solid state nitrous solenoid before heading back to the track. Good thing the nitrous wasn't working though as it would have just made things uglier at the track - I need to dial in the car w/o nitrous first - May 30, 2017

After some more static nitrous system testing I determined that the tiny 5mm OD nylon nitrous line from the trunk to the engine was restricting flow so I removed the jets from the NOS Wizards Quadranoid and used the adjustable plunger to set the flow rate. In the process I managed to rip the o-ring seal and also over tighten the plunger and damage the teflon plunger seat so it was leaking badly - so I ordered a new solenoid and continued with my testing ...

With the plunger seat set fairly close to the fully 'off' position (about 1/2 turn) I ended up with around 65hp of nitrous flow to the engine. PWM control testing showed flow from around 25-80% (below that it doesn't operate and above that it flows around 100%) and it was not entirely linear - as in 50% PWM gave around 40hp of nitrous flow.

Street testing was initially done at part throttle at 30/50/100% PWM setting with manual activation - to verify that things were within an acceptable A/F ratio range. This type of testing has limitations as it is hard to hold the throttle steady enough for consistent ECU performance - the 'CL Comp' value (closed loop compensation of A/F ratio) is very sensitive to TPS (throttle position) so it is only a rough measure of how rich/lean the ECU nitrous programming is. Anyway, it showed that I needed to adjust the nitrous fuel tables up to 30% which I did do.

Street testing at full throttle and 100% PWM was quite a handful: there is NO traction in 2nd gear - within 0.5s the RPM jumps from 3,500 to 7,000rpm as the street tires spin. The tires hold in 3rd gear with a dramatic rush from the sudden increase in torque - it is like a turbo with zero lag. Very impressive.

Post street testing, a look at the ECU datalogs indicated a 0.1s lean condition on initial nitrous flow so I turned off the default 125ms fuel delay setting - the nitrous was getting to the engine before the fuel was and this was causing the ECU to try and add fuel to compensate, resulting in an over-shoot/under-shoot instability in the A/F ratios for about 1.5s until settling down to my target 13:1 ratio. Things should be much more stable now - and I will find out Friday at the drag strip. And hopefully 2nd gear will hold with the drag slicks.

I also installed a solid rear transmission/motor mount - I modified it a bit with some rubber padding - it does cause increased vibration in the chassis but it is liveable for the limited period of time I will need to have it installed while racing.

Ted/Jetfab made me some nice aluminum ramps to allow me to drive on/off my EZ car lift - it will come in handy when I store the GTI in a single car garage on Vancouver Island this summer.

Finally, I installed a brake duct cooling system and switched over to the Hawk DTC-60 race pads - they are now bedding in and the car is therefore ready for the road course testing this weekend. I also installed the passenger Sparco racing seat and harness so I can have the instructor with me ...

- July 4, 2017

I made the epic journey to both the Mission Raceway and the Vancouver Island Motorsports Circuit over the past weekend, towing my GTI with the EZ Car Dolly behind our Highlander. The wheel/tire straps were too large and I didn't realize they were adjustable for width and length so I managed to bang up the control arms and rip at the fender flares but no other towing issues were involved. I have new ordered 'fixed' straps for smaller wheels like mine which should help a lot - the adjustable straps are a pain to use and aren't as secure as fixed straps are.

With the nitrous system working properly I was keen to get some nitrous 1/4 mile passes in. The first baseline pass without ntrous was another 13.8s time slip with some wheel slip again off the line. The 2nd pass was with 33% PWM on the nitrous (around 25-30hp) and I ended up with the clutch slipping in all gears. I thought it was tire slip so I put on the stock wheels and tires to see if the slicks were the issue and the car ran without clutch slipping, but I hit redline in 3rd gear before the 1000 foot mark and forgot to shift into 4th until too late and missed the shift - the car ran a 13.4s time slip so it would have hit high 12s if I hadn't shut-off so early and coasted. But the mystery of the clutch slip remains and I'll have to look into it more later (it didn't surface again at the road course). The fact that my street tires had better traction than my slicks seems to be related to the 1.3 degrees of negative camber - the slicks are very wide (about 9.5") and don't sit flat enough on the road surface. I only had 45 minutes of total racing time available as the track opened late and I needed to drive 100kms to the ferry terminal for a 2pm departure ...

I got to my new GTI storage garage at Parksville and setup everything before the end of Friday night. I washed the GTI and prepped it for the 100kms morning drive to the track early Saturday. The Hoosier tire engineer/sales rep was there to show off the new A7 racing slicks and I was proud to say I had brought my own set of A6 tires (a lower temperature compound version) but I had mistakenly brought only 2 A6s and 2 DR2 drag slicks so I could only run on the street tires on Saturday - I planned on returning Sunday to run with the A6s but disaster struck late in the day for me Saturday ...

My first time around the road course in the GTI was thrilling. My line and technique was rusty and far from perfect but I hustled around the track at speeds higher than the other Porsche Cayman S track cars were capable of. By example, I was 150-155km/h at the top of the track long straight vs 140-145km/h for the Porsche Cayman S cars and had a lap time a bit faster. I had higher acceleration, equal braking, and almost equal corning power (estimate only - no g force data logging to back this statement up - TBD in the future). The suspension was quite neutral so when I overpowered the car into and around the corners the car simply drifted sideways. Yes, there was some typical FWD pushing when I tried to accelerate too hard out of the corners but we were all amazed how well mannered and dialled in the suspension system was for a '1st timer'. I don't think I'll change anything about the suspension. Some other folks drove the car and thought the suspension was too stiff but I felt it was perfect and since it is acceptable on the street and it is dead flat at the track I have zero complaints.

The Tech53 brakes with the racing Hawk DTC60 pads were the highlight of the day at the track - those brakes were awesome! They hauled the car down from 160km/h like I was hitting a tire wall each time. No fade, no modulation issues - just pure high octane stopping power. Wow.

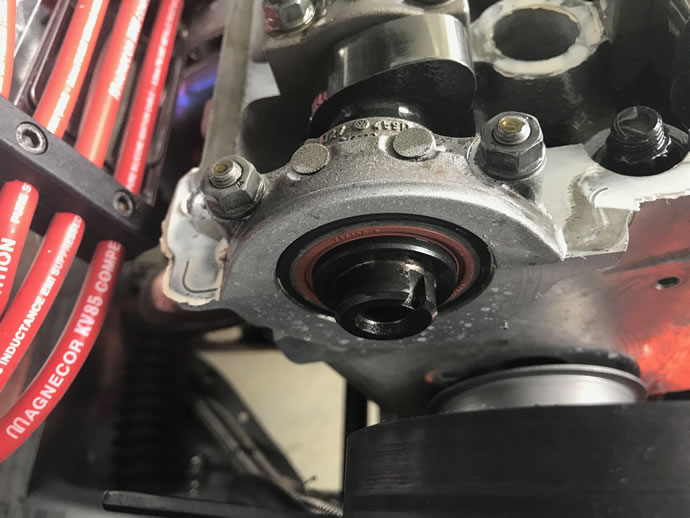

I finally convinced the lead instructor to drive me around the track but he was babying the car too much so I egged him on to rev past 8000rpm and push deeper into the corners, which he finally started to do. He admitted that the GTI 'has very good acceleration'. Then the engine 'note' suddenly developed a raspy edge and I knew something was failing in the engine bay so I madly waved him to pull off the track and killed the engine. I captured all of this on video and you will see that it took a while to find out what was causing the problem: the adjustable cam sprocket had vibrated apart and was only holding together with 2 partially loosened bolts with the sprocket wobbling wildly. I found out later that the issue was the crank damper/pulley fasteners backing off enough to let the pulley get out of balance and that increase in vibration, plus the solid trans mount, put enough added stress on the sprocket, plus the extended 8300rpm use ...

Timing marks were still in alignment but the question will be whether or not my 12:1cr pistons and 34mm intake valves and 288 race cams would allow for wide variations in cam timing and NOT bend all of my expensive valves. I will do a full inspection next week and find out - fingers crossed. I have INA Engineering machining me a new fluidamper with a custom steel spacer and lip press-fit together with new OEM bolts - the substandard aluminum spacer will go in the garbage. I will also install a better cam sprocket and new ABF timing belt- July 11, 2017

All good! Pistons and valves did not appear to touch each other. My initial commentary in my videos indicated otherwise because you can see small shiny areas in some of the intake valve reliefs in the pistons. But Josh, my engine builder, says they are simply camera light reflections on the shiny areas that are from the turbulence caused by the valves coming so close to the pistons during normal use - similar to what happens to the squish area of the combustion chamber where the top of the pistons are shiny too.

I used a bore scope to inspect and take photos of the pistons and then conducted leak down and compression tests on all cylinders. With a 90psi input pressure the leak down for all cylinders was in the 4-6psi range. The compression tests ranged from a low of 180psi to 210psi - again, Josh says that the variability is not an indication of valves being bent - if they had been bent compression would be terrible, same with the leak down results.

I was about to start putting the engine back together when I realized that the beautiful, sturdy new Kent cam sprocket didn't have an integrated key so I got on the ferry and left for the week. I contacted the supplier and they pointed out that there is a half-woodruf key supplied in the box which I didn't notice. In any case, Fred/Tech-53 has lost a few motors from these aluminum sprockets failing (aluminum fatigue around the key area when used with aggressive cam profiles and high rpm) and strongly advises people to steer clear of them. He is sending me one of the modified (and heavier) steel OEM units that are setup for adjustability. I am also going to change my rev limiter to 7,600rpm to avoid punishing my nice motor - it produces its peak power closer to 7,200rpm and so revving up to and past 8,000rpm with my heavy 95.5mm stroker crank isn't necessary or good for the longevity of the motor anyway.

Josh says to only use the cam sprocket adjustability to 'zero' the cam in. When he did it the cam was lined up exactly at 'zero' on the scale so I guess I could simply use an OEM steel sprocket which would be highly reliable. I'll order one as they are not expensive and will also get one of Fred/Tech-53's adjustable all steel sprockets. Josh's comments on advancing the cam to lower the power peak is to not bother as it won't typically help - he wants the cams at true 'zero'.

Another thing Josh pointed out is that people tend to set the cam belt tension too high, causing excessive wear on the 1st cam journal bearing and the intermediate shaft bearings - his point is that once an engine heats up it will expand so the 45 degree finger twist test should be slightly lose when cold - July 19, 2017

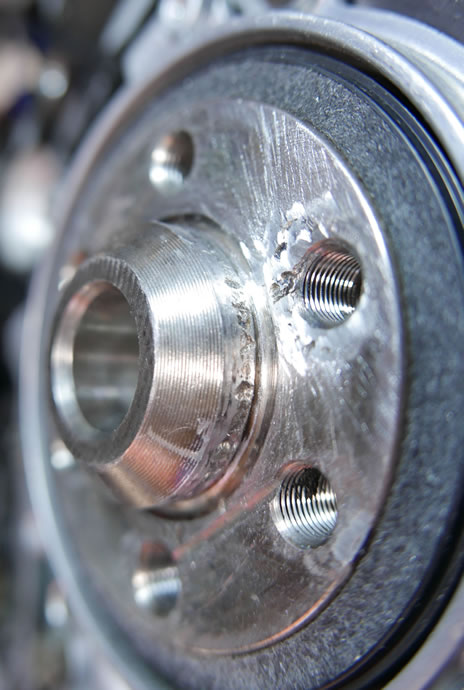

Issam at iABED Industries (formerly INA Engineering) made me up a trick custom Fluidamper assembly on a rush basis with many thanks. It consists of a slightly turned out (32mm ID) fluidamper with a press-fit steel 6.2mm spacer that will mount 'hub centic' to the ABA crank sprocket. I will use grade 12.9 allen head bolts, lock washers and locktite 242 and will torque to spec. The aluminum spacer and previous Fluidamper damper will be sold if anyone wants it (it would be fine for a non-race lower rpm motor) - July 20, 2017

I decided after subscriber feedback that the Kent adjustable Cam Sprocket was strong enough to be used so it is now installed, with Locktite 242 and prep spray, torqued a bit higher than the OEM 45 ft-lbs spec, plus I installed a new timing belt as the other one had been thrashed and potentially stretched with the cam sprocket wobbling as much as it had. I installed the custom INA fluidamper assembly with 8x30mm grade 12.9 allen head bolts, lock washers and the same locktite 424/prep spray as for the cam sprocket and torqued it all properly. I then fabricated a new alternator bracket as the other one had snapped when the damper had shifted, and I was keen to sort out a finely adjustable bracket that was stronger - mission accomplished.

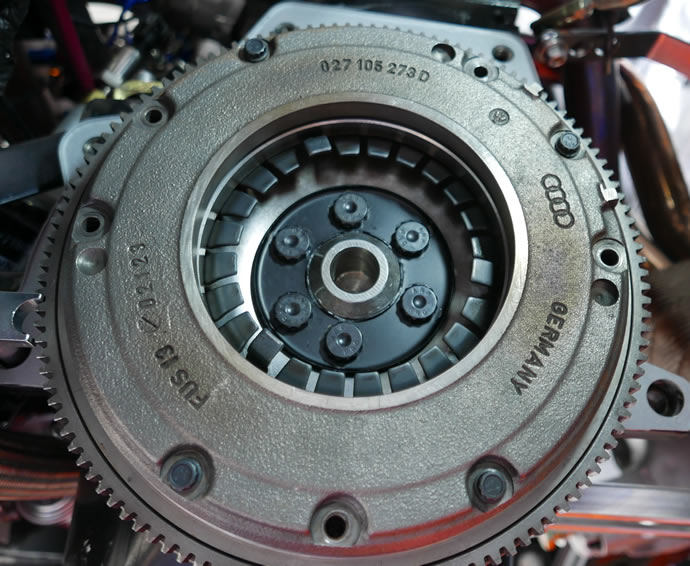

After all of the re-assembly work ,measuring the lash of my solid lifters (all within spec and on the tight side @ 0.008-0.010" intake and 0.012-0.015" exhaust) putting the cam cover back on with some RTV, etc. I cranked over the engine with the starter (ignition off) and there was a nasty clicking sound coming from the bell-housing. This sound was not present 2 weeks earlier when I was testing the engine for potential piston-valve damage when I did leak-down and compression testing, but I realized that I had done that testing without spark plugs installed and this was the 1st time I had the engine fully back together and the cranking while under full compression with 12:1 pistons ....

So I looked carefully at the clutch pressure plate and found that it was slightly lose - I could move it back and forth a few degrees so those critical bolts that hold the pressure plate to the crank had also worked a bit lose when the damper had shifted. Who knows, maybe the pressure plate bolts were the 1st ones to back off and the damper bolts worked lose next, then the cam sprocket assembly? I will never know. But I do know that 8300+rpm and my large 95.5mm stroker crank is not a great combination so that is why I am keeping my max rpm to 7,600rpm from here onwards ...

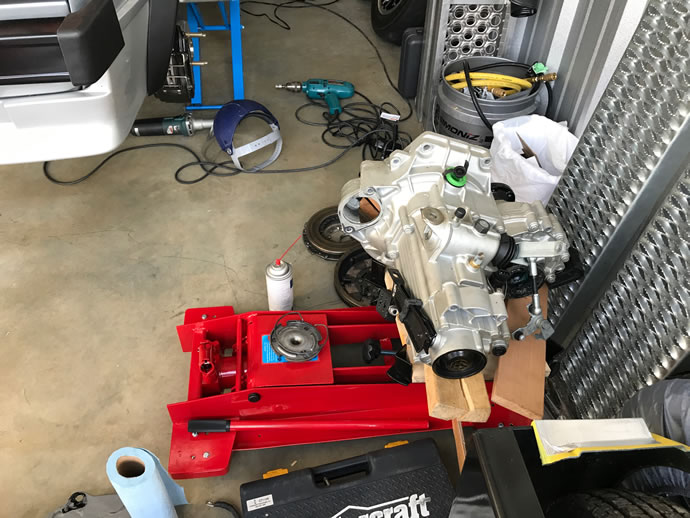

So the car won't be on the road again for a few more weeks as I need to drop the transmission out of it, remove the clutch assembly and install new racing Techtonics/ARP pressure plate bolts. This requires me to source an engine support bar and a transmission hoist which are now ordered. What a pain ... but I did have some significant clutch slippage at the drag strip and there is a lot of black clutch dust all over the inside of the bell housing so I want to inspect the clutch and decide if I need to change or upgrade it further (it is a custom racing clutch but it may need to be stronger if I want to use nitrous with it).

I went to the VIMC track today and rented a 2017 M3 which has the same wt/pwr ratio as my GTI and it was a lot of fun. The car feels heavier for sure (3600lbs vs. 1900lbs) but it has big brakes and lots of low-end torque so it pulls harder out of the corners and seems to have stronger brakes. I will be back on the track with it later this week and will record the lap times and g forces and when I get the GTI to the track I will have comparison data. The M3 is faster than the Cayman S I drove at VIMC ... - August 6, 2017

Hmm. I should have been nicer to my shiny new GTI rather than immediately take it to the drag strip for 20 passes at full throttle, with nitrous and slicks, slipping the crap out of the clutch.

Lesson #1: street cars are meant for the street, race cars are (built) and meant for the strip/circuit track. Yes you can take a street car to the track but it won't like it much, putting a lot of stress and premature wear on all of the critical parts. Either you build a race car that has a race clutch, high rpm engine components (and fasteners) and brakes or you take your street car to the track and you don't massively abuse it or try to run it at 10/10th continuously.

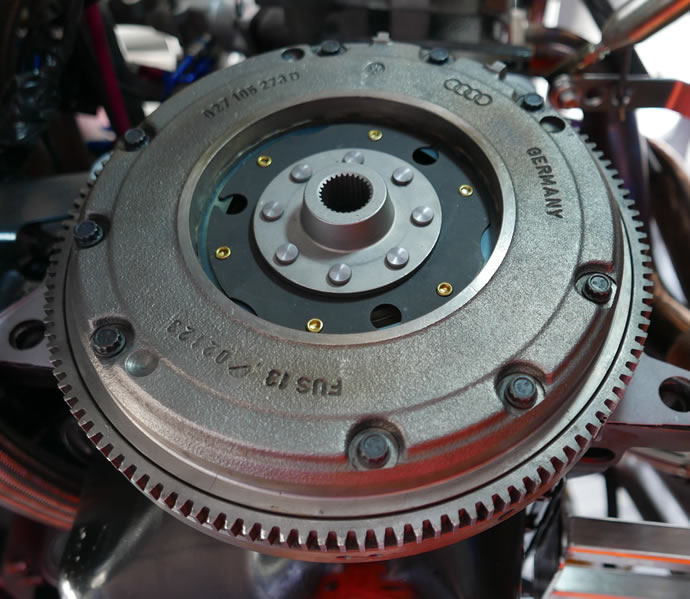

After getting the engine support brace and the transmission hoist setup I pulled the trans out and it wasn't too much work for a single person job. I had more trouble getting the axles out than actually pulling the trans out. When the clutch pressure plate wouldn't come off the crank snout I knew I was in trouble. Yes, the fasteners as suspected had backed off, but that caused a violent back and forth friction between the pressure plate that heated the metal up so much that it actually melted and fused the components together. The fused metal had broken back apart but it was internally rutted/scared such that the pressure plate would not rotate more than 5 degrees and would not separate from the crank despite dozens of hammer blows ….

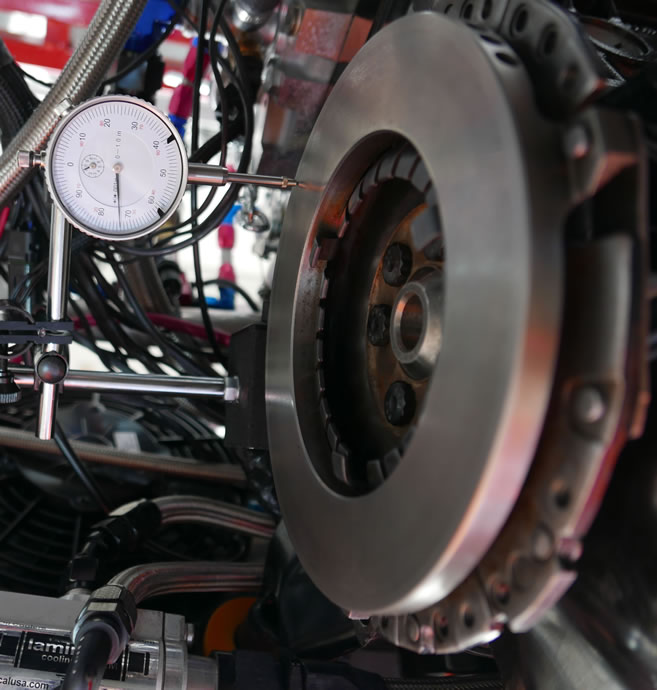

So I did the unthinkable and I took my die grinder with a cutoff wheel and I sliced thru the ¼” thick pressure plate from bolt hole to bolt hole, and yes I could not completely avoid cutting into the crank face in a few places and then I was able to rip it off, then I cut thru the remaining ring at one location and spread it apart and pulled it off. The crank snout was a bit ripped up and so were some spots around the bolt holes but in general it was fixable with the die grinder and a flat file to get the surfaces level and smooth again. True, there are a few uglies but I am quite confident that I don’t need to remove the crank and re-weld and machine it. I’ll put the new pressure plate on and use a run-out dial micrometer to verify that it is true before continuing to assemble the rest of the transmission.

And yes, the high performance clutch friction plate was worn out already so that limited drag strip time was very very hard on the clutch. Josh and I texted about this and it turned out he had a Kennedy clutch assembly on hand that he will ship to me. It has about 20% more holding power than mine so that should be a good upgrade. I won’t be slipping the clutch at the strip if I go back and I will learn proper heal and toeing for the circuit and won’t abuse the clutch any more. And I have already reset the rpm limiter to 7600rpm, down from 8300rpm.

So I think the clutch pressure plate failure caused all the other failures – setting up the engine for extreme vibration, causing the pulleys to back off as well. Ouch! - August 31, 2017

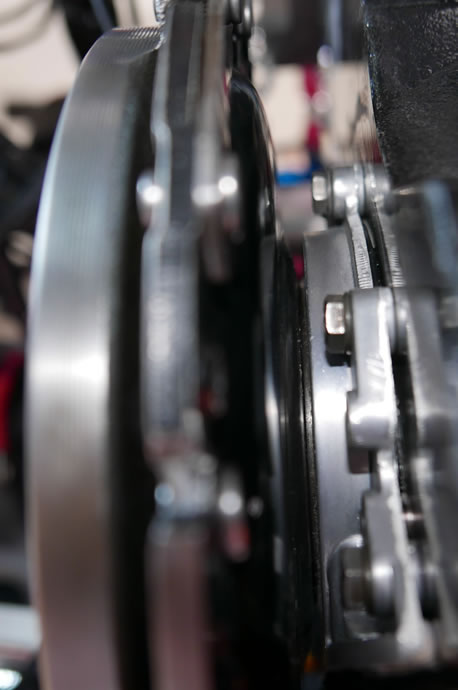

Josh Arnold, my engine builder, came to my rescue by rush shipping his personal clutch assembly to me. I installed it today, put everything together carefully using ARP pressure plate fasteners and Locktite 262 thread locker, torqued to 60ft-lbs, checked the runout at the outter most edge of the PP (+/- 0.012") and then bolted the transmission and axles back on, plugged in the wiring harnesses, cables, etc. and then started it up and drove it around Parksville/Qualicomm Beach for 2 hours as the sun was setting. It was bliss. I also installed a USRT clutch cable termination assembly and had some fun testing out the new poly steering rack bushings: yes, they eliminate the rubbery feeling of the stock bushings without adding any addition vibration - I am super happy and think they will make track days much more rewarding - especially with slicks mounted.

FYI, the new pressure plate is about 20% stiffer with more clamping force which is important - it feels grabbier - hopefully it will handle a little nitrous - unlike the prior setup. I also went ahead and ordered a 6 puck sprung racing clutch setup from California Clutch today as I want a backup unit that is even stronger than my newest one. I don't really want more pedal pressure but I'd like to be able to use 80hp of nitrous at the drag strip without frying the clutch.

Re the Kennedy clutch assembly: I sent photos of my old and new assemblies to California Clutch and they laughed and said 'that is our friction disk, not Kennedy's and the older PP unit is a modified Sachs unit. They said Josh had custom ordered some friction disks from them with a hybrid organic compound on one surface and metallic on the order side and no springs. I was going by what Josh said to me, and it was all shipped in a Kennedy box and the back of the PP was indeed stamped 'KEP stage 1'. So it looks like the PP is a KEP unit but not the disk.

It will be interesting to see what California Clutch sends to me ... (the 6 puck sprung unit). I am not really keen to pull the trans out any time soon but if I have any more issues with my new clutch I will not hesitate to swap in the 6 puck unit since I have all of the necessary equipment now (engine support, trans hoist, experience, etc.

When I re-installed the transmission I used the USRT clutch cable termination block - a much nicer solution than the OEM h/w.

I also had the chance to check out the HD poly steering rack bushings - they are awesome: no increase in road vibration but all of the rubbery feel is now gone from the steering and that all-important initial turn-in is crisp/precise now) - September 8, 2017

comparing the old and new friction disks - the old one isn't worn as much as I thought it was ...

Verifying that the new PP is sitting flat on the crank surface ...

I had a chance to get over to the island and prep the car for the required safety inspection at the local BMW dealership that is owned by the same group that owns the track and, yes, I passed the inspection. It was nice that the service technician was a former VW mk1 racer who really understood what this project is all about. I got to the track and mounted the Hoosier slicks and then took it for a slow lap to see if there were any issues: the 1st corner told me that there was some rubbing of the slicks on the rear fender wells so I am ordering another set of H&R race springs and will not cut them this time - that should give me 1/2" of additional ride height, plus I'll move the rear spring perch up another 1/2" which is where there is the most suspension movement (I'd like to go with rear springs that are 20% stiffer as the car still under-steers a bit at the track but I don't have a source). I drove the car home on the slicks just to get more 'seat time' with them and found that they really transformed the steering response - perhaps too immediate with the short wheel base. At 120kmh a 1" steering change results in a pretty fast lane change. I will just have to get used to it. The street tires will never feel as good now.

Update: I ordered the Ground Control coil-over adapter kit with 430/350lbs/in F/R springs after discussing my needs with them. They could not tell me what the H&R race spring rates are but felt that for a car that will see track days and will be using my 28mm rear bar and no front bar, the 430/350 combination would be a good starting point. They offer springs at 50lbs/in increments so I can make future changes - including going softer in the future when I retire the car to be street use only in a year or two. I like the ability to quickly adjust ride height too. They made an observation re. the H&R race springs which have many 'dead' coils and only a short active spring compression distance: weekend track day H&R race spring users complain of coil binding and the non-linearity that results - the springs can 'bottom out'. The GC springs are linear w/o dead coils so will have more potential range of motion. Finally, I ordered Lella 10mm rear axles spacers to replace my 15mm spacers to give me more room for the slicks - this in combination with some increase in rear stiffness and a slight increase in ride height and all should be well - rubbing wise ... - September 20, 2017

Rather than playing around more with the H&R race springs I ordered Ground Control Coil-Over Adapters with 7" 430/350 lbs/in front/rear springs which we determined would be a good starting point for more neutral cornering dynamics and fully adjustable ride height at each corner. After installing them it became clear that the 7" front springs were too tall, making the car sit up 1” higher than ideal (I like about a ½” gap at the fenders) so I have ordered another 440 lbs/in 6" set - the rears were fine. The car is now much stiffer in the rear and it makes driving on the street somewhat harsher, but really, it doesn't bother me too much. I'll back off to 300/200 lbs/in when I retire the GTI from the track in a year or so but right now the 430/350 combination along with the Autotech 28mm hollow rear bar is providing very neutral and stable cornering with slicks on the track.

The car is handling superbly now - it is really quite shocking how quickly it goes around the corners without a fuss - just point the car at the apex and the car immediately goes there without tire squeal or understeer. Never in my wildest dreams did I think my GTI would handle this well - it is world class now. My best lap time in the new 718 version of the Porsche Cayman S (0-60mph in 3.6s and 1/4 mile in 12.0s @ 120mph) using Continental's best street performance tires was a 1:33s time, while I managed a 1:31s time in the GTI while keeping the rpm well below 7000 for 95% of my shifts (average of only 3400rpm) and coasting around many of the corners, soft braking into the corners, having relatively cold tires (the air temp was around 16 degrees C but the track surface was colder as the overnight temps were only 7 degrees C), etc. I am confident that I'll get the GTI into the 1:25s range in the spring when my ride height is down another 1" and the track and tires will be at optimum temps - and when my driving skills and experience on the track have also improved considerably (like learning how to heal and toe properly with my modified wider and longer gas pedal).

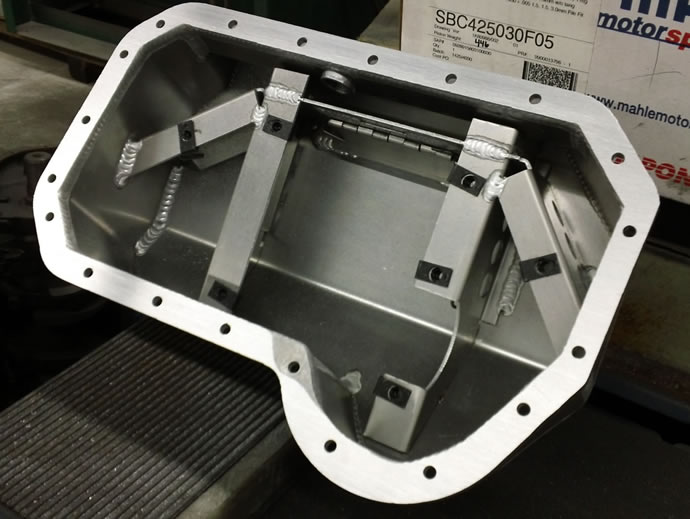

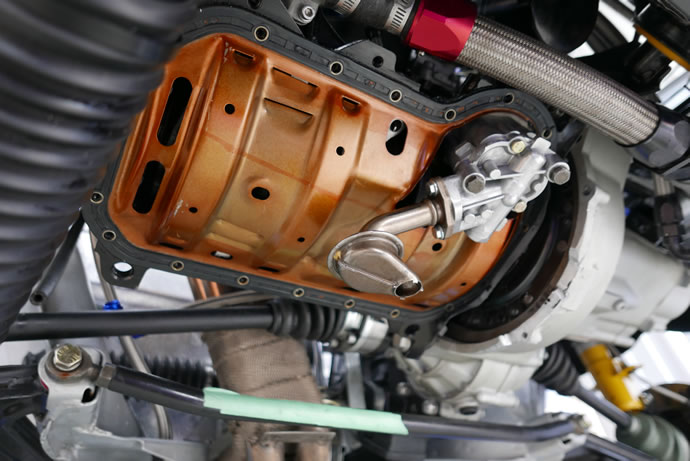

One problem I did have was that after the 3rd set of laps on the track I puked up a lot of oil which came out the PCV breather filter and splattered all over the drivers side of the engine bay making a big mess and likely getting some oil on the track surface as well, which is totally uncool. We inspected the track and couldn't see any oil so didn't shut down the track but I felt bad about it and need to solve this problem (oil sloshing forward under heavy braking with slicks and getting out the PCV port at the front of the ABA block) so I have accepted a generous offer from Mike Fopeano, a fellow VW Vortex member, and Mk2 owner/enthusiast, and purchased his mint condition INA Engineering racing windage tray oil sump and will also rig up a racing oil catch can/breather system with a sump return line that plumbs into the INA sump with a separate fitting - this return line will be controlled with a ball valve to as to not risk water based contaminants returning to the oil system under normal use, but at the track where larger volumes of oil can splash out and risk trouble the oil will be recycled.

I check the ECU data logger and at no time did I lose oil pressure around the track - October 7, 2017

Heading back home on the ferry afterwards ...

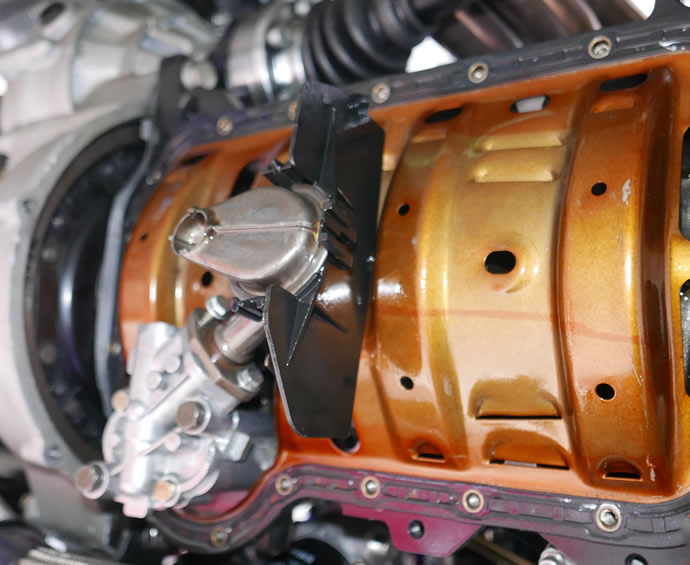

The INA oil windage sump system - courtesy of Mike Fopeano, a fellow VW Vortex member, and Mk2 owner/enthusiast...

I finally had the time to travel over to my new GTI guy garage on Vancouver Island and start the process of building a track-ready oiling system that includes an INA oil pan and an external racing oil catch can with return line. It was cold and damp and so I was freezing my ass off but I managed to pull off the OEM oil pan, pump/pickup and windage tray and start the process of fitting the INA pan to the block and clearance the transmission bell housing (which required a lot of work - tisk, tisk, INA, this wasn't even close to fitting out of the box, plus the 2 hard to reach mounting holes next to the transmission were mis-placed and will require slotting). So after a lot of effort I managed to get the INA pan to fit-up to the block and trans and then measured for the custom racing oil catch can.

The idea for the new oiling system is 4 fold: increase the amount of oil from 4.7 to 5.7 quarts, reduce the tendency for oil to slosh away from the oil pump pickup, provide an external catch can that will keep any oil that finds its way out of the PCV port on the front of the block to a 1 quart reservior, and finally, provide a return line to the oil pan via a one-way 'check valve' - so that oil that pumps out of the PCV port can find its way back into the pan - this is a race track system and will not be necessary on the street. I have now ordered the custom catch can and sourced the lines and fittings so once it all arrives I'll be able to assemble it all.

In addition to this oil system track-only upgrade, I sourced a 2 axis accelerometer as my custom 3 axis unit is too noisy and is therefore close to useless, plus I now have my Ground Control 6" 440lbs/in front springs that I will install. After running the car for a while with the 7" springs, the fender gap settled to 1.25" and so I will lower the car all-round to a 0.5" gap - I highly doubt I will have any fender rubbing with the wide Hoosier A7 slicks as the springs are super stiff and there is very little body movement at the moment - November 16, 2017

The OEM windage tray will be retained but the plastic divider had to be removed (the windage tray was leaking oil so I have removed it and will re-seal everything when installing the new INA pan) ...

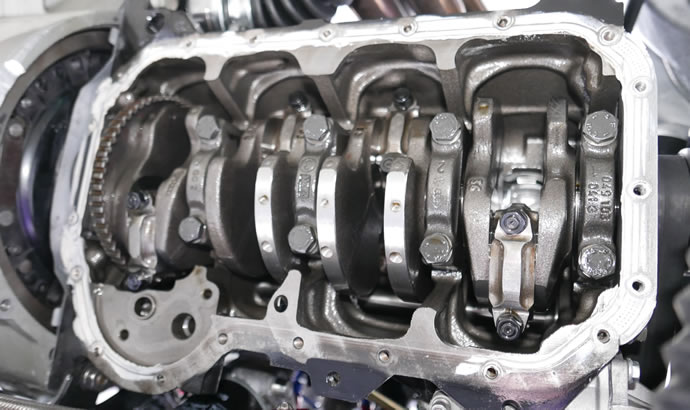

That bad-boy 95.5mm crank and rods look nice ...

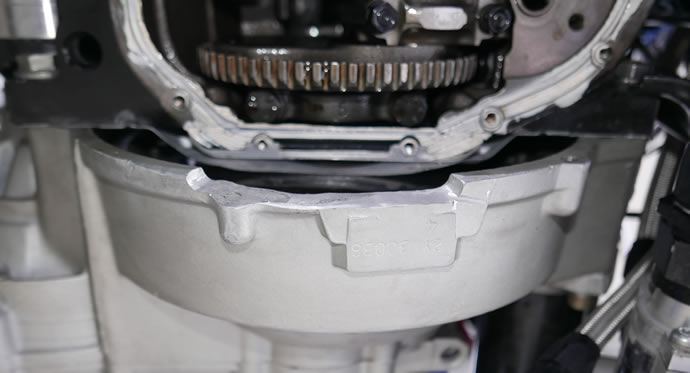

Notching out the bottom lip of the transmission bell housing was required to clear the one-off INA custom oil pan - rats ...

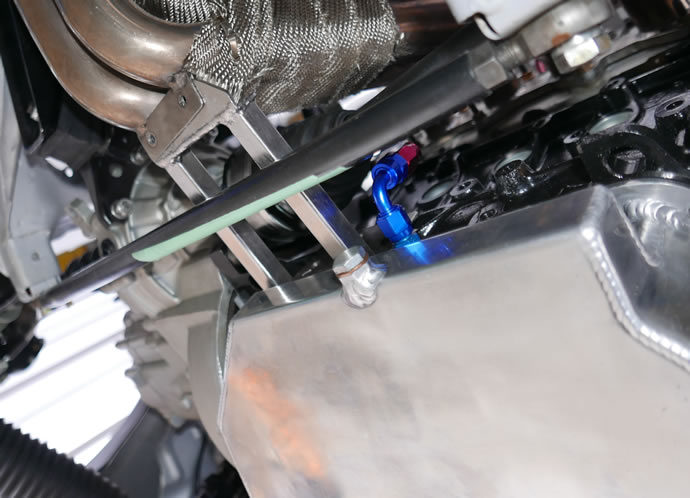

I am lucky that with only minimal mods the racing exhaust header support bracket now clears the rear extension of the INA oil pan, plus the oil return line from the oil catch can also clears the bracket ...

Once installed, the INA pan does look the part on this project car ...

It has been a long while since I posted a project update. My spouse was diagnosed with an aggressive form of Breast Cancer in late November and we have been in and out of the hospital and cancer agency 100 times since then having tests run, surgery performed, more testing, and now chemo (followed by radiation and more drugs). She is taking the abuse well enough and we are trying our best to keep soldering on with our daily lives but in reality everything has changed for us and we are trying to find a 'new normal' in the madness of it all. Everyone has been really great - we truly feel blessed even though we realize that this is a life threatening disease.

My spouse wants me to find ways to be happy and reduce my stress so my GTI project is there for me and now that we are into a long period of chemo it is a good time to start to move forward again as the winter starts to change into early spring in the pacific northwest - I want to get back to my Vancouver Island guy garage next month and start to put everything back together and get ready for some track time to debug the new oiling system.

I got a custom fabricated 1 quart can made up by www.racecatchcan.com with a 1" NPT intake bung and a -6AN drain that I will mount where my electrical A/C compressor normally sits (I will use the same mounting holes). I need to fabricate the mounting bracket next and then hopefully I can simply get back to the GTI and start to bolt everything up (yes, I'll need to make up some custom length -6AN SS lines to connect the drain thru the 1 way valve and then to the oil pan drain line port).

After some searching and testing I found that I needed to use a very specific type of 1 way 'flapper' valve (Earls P/N 251006ERL) as I needed just the force of gravity to open the valve and let the oil drain back to the pan. Other spring engaged 1 way valves took too much pressure to work in my situation (they are designed for pressurized systems like fuel lines). Lesson learned. I need the 1 way valve to protect the catch can from reverse flow of the oil in case there is any momentary pressure on the oil in the pan from acceleration and/or oil plugging up the PCV port on the front of the block during hard braking - I am not sure I need it but think it is a good precautionary move to make - January 18, 2018

I finished making the racing oil catch can bracket and sourcing the necessary parts to put my racing oil system into the GTI this past week. The temperatures were still cold here in the Pacific Northwest so after a long day in 6 degree C temperatures under the car I was pretty fozen but the job was completed, along with the installation of the new 6" 440lbs/in front springs and lowering the car all round to a 3/4" fender gaps with the slicks on. I had to clearance the transmission bell housing a bit more to gain access to the oil pan bolts next to the transmission (the next time the trans comes out I will clean up the area a bit more as it is still really hard to get those 2 bolts in). I used Toyota oil pan caulking to first adhere the OEM windage tray to the block with the INA oil pan torqued up to hold everything in place, then I pulled the pan off again, installed the oil pump and pickup, applied the next layer of caulking, and put it all together. The racing oil catch can and plumbing all worked out very well, especially considering that I had to guess a bit when fabricating the mounting bracket and designing the lines (being 100kms away in Vancouver at the time). The only tricky part was ensuring that the oil return line and one-way valve didn't rub against either the tranmission linkage or the CV/axles which are only 1cm away ...

After the oiling system was successfully completed, I pulled out and re-installed the oil dip stick tube which was also leaking a bit at the base - again, I used the Toyota oil pan caulking to ensure a good seal. Then I pulled out the front struts and swapped out the 430lbs/in 7" springs for 440lbs/in 6" springs, and then adjusted the ride height all the way around the car for 3/4" fender gaps (the car will likely settle a bit once it has been driven so I guess that it will end up at around 1/2" which I hope will not rub at the track - if it does, it will be a quick adjustmnt to add back the 1/4" or so). Finally, I attempted to perform a camber alignment but ran into the limitations imposed by the wide rims and slicks which limit the amount of negative camber that I can set without risking the tires contacting the struts under cornering loads at the track. With a 1/4" side gap to the strut body I could only get around -1 degree dialed in (while using 5mm wheel spacers which is the max I want to use) so I have sourced very nice CNC'd adjustable camber plates from Silver Project in Poland that mount to the OEM holes. When I get them I'll go back to the GTI and install them, setting the camber to -2.5 degrees, and will also install a new 2-axis accelerometer and then get the car on the road again for some pre-track testing mid April - March 30, 2018